博文

用细菌将空气中的二氧化碳转化为聚酯纤维

||

用细菌将空气中的二氧化碳转化为聚酯纤维

诸平

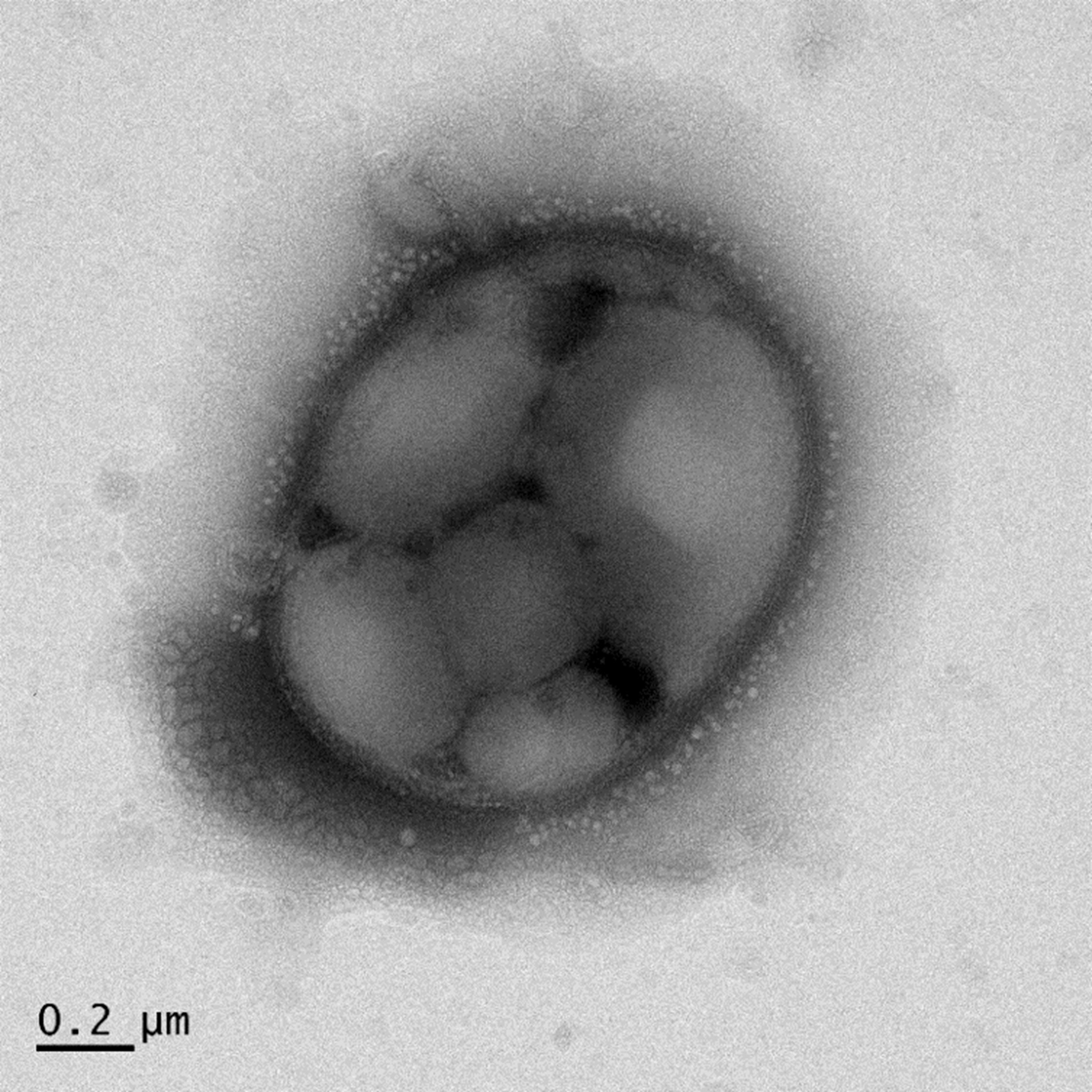

C. necator cell accumulating poly-3-hydroxybutyrate (white granules inside). Credit: Jinkyu Lim

据物理学家组织网(Phys.org)2023年3月28日报道,韩国先进科学技术研究院(Korea Advanced Institute of Science and Technology简称KAIST, Daejeon, South Korea)的一个化学和生物分子工程(Chemical and Biomolecular Engineering)团队开发出一种可扩展的方法,利用细菌将空气中的二氧化碳转化为聚酯纤维(Using bacteria to convert CO2 in the air into a polyester)。相关研究结果于2023年3月27日已经在《美国国家科学院院刊》(Proceedings of the National Academy of Sciences)网站发表——Jinkyu Lim, So Young Choi, Jae Won Lee, Sang Yup Lee, Hyunjoo Lee. Biohybrid CO2 electrolysis for the direct synthesis of polyesters from CO2. Proceedings of the National Academy of Sciences, 2023, 120 (14): e2221438120. DOI: 10.1073/pnas.2221438120. Epub 2023 Mar 27. https://www.pnas.org/doi/10.1073/pnas.2221438120

在此论文中,研究小组描述了他们的技术,并概述了在几个小时内进行测试时的表现。

随着气候变化(climate change)的进展,世界各地的科学家继续寻找既能防止排放又能从空气中清除排放的方法。在这项新的研究中,研究人员再次研究了使用一种细菌(bacteria, Cupriavidus necator)从空气中吸收二氧化碳,然后用它来制造一种聚酯的可能性。

先前的研究表明,C. necator可以吸收二氧化碳,并用它来制造某些类型的可生物降解塑料。但这一过程只能分批进行,因为启动这一过程需要电力(electricity),且有毒副产品会积聚并杀死细菌,这阻碍了此工艺的缩放进程。在此次新的研究中,韩国研究组克服了这一问题。

解决办法是在过程开始时添加一层合成膜(synthetic membrane),将细菌与有毒副产品分离开来。这导致了一个双边进程(two-sided process)。在一边,化学反应(chemical reactions)为发酵准备了二氧化碳,而另一边则储存了其他所需的成分。然后,薄膜允许这些成分缓慢地流向细菌的一侧,细菌利用它们制造出少量的聚3-羟基丁酸酯(poly-3-hydroxybutyrate简称PHB)。

研究小组进行了这一过程,持续了18天。期间包括定期去除附着在PHB上的细菌,并添加新鲜的空样本。他们发现,这种方法能按计划工作,而且每小时能产生11.5 mg的PHB。研究人员指出,这个过程仍然需要电力,但由于它比其他方法更有效,将二氧化碳转化为聚酯的成本要低得多。他们还指出,这个过程可以很容易地扩大规模。

本研究工作得到了韩国国家研究基金的资助(National Research Foundation of Korea: NRF-2017M3D1A1040692; 2021R1A3B1076715; 2022M3J5A1056072; 2022M3J5A1056117)。

上述介绍,仅供参考。欲了解更多信息,敬请注意浏览原文或者相关报道。

Although the electrochemical reduction of CO2 into chemicals has been actively explored to address climate change, the products are mainly limited to C1-3 products. Herein, we show that the integration of CO2 electrolysis with microbial fermentation can efficiently produce value-added multicarbon products such as poly-3-hydroxybutyrate (PHB) from gaseous CO2. This biohybrid system comprises electrochemical conversion of CO2 to formate and subsequent biological conversion of formate to PHB by Cupriavidus necator. Optimization of the system to secure suitable conditions for both conversions allowed continuous production of PHB with high titer and productivity which is two orders of magnitude higher than the reported values. This work proposes an exceptional strategy for lowering CO2 emission and producing environmentally friendly bioplastics.

Converting anthropogenic CO2 to value-added products using renewable energy has received much attention to achieve a sustainable carbon cycle. CO2 electrolysis has been extensively investigated, but the products have been limited to some C1-3 products. Here, we report the integration of CO2 electrolysis with microbial fermentation to directly produce poly-3-hydroxybutyrate (PHB), a microbial polyester, from gaseous CO2 on a gram scale. This biohybrid system comprises electrochemical conversion of CO2 to formate on Sn catalysts deposited on a gas diffusion electrode (GDE) and subsequent conversion of formate to PHB by Cupriavidus necator cells in a fermenter. The electrolyzer and the electrolyte solution were optimized for this biohybrid system. In particular, the electrolyte solution containing formate was continuously circulated through both the CO2 electrolyzer and the fermenter, resulting in the efficient accumulation of PHB in C. necator cells, reaching a PHB content of 83% of dry cell weight and producing 1.38 g PHB using 4 cm2 Sn GDE. This biohybrid system was further modified to enable continuous PHB production operated at a steady state by adding fresh cells and removing PHB. The strategies employed for developing this biohybrid system will be useful for establishing other biohybrid systems producing chemicals and materials directly from gaseous CO2.

https://blog.sciencenet.cn/blog-212210-1382777.html

上一篇:《自然》:实验发现质子中有胶子质量

下一篇:《科学》:人工智能比主流工具更能预测酶的功能