博文

Steps Toward Industry 5.0: Building “6S” Parallel Industries

||

Citation:

X. X. Wang, J. Yang, Y. T. Wang, Q. H. Miao, F.-Y. Wang, A. J. Zhao, J.-L. Deng, L. X. Li, X. X. Na, and L. Vlacic, “Steps toward Industry 5.0: Building “6S” parallel industries with cyber-physical-social intelligence,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 8, pp. 1692–1703, Aug. 2023. doi: 10.1109/JAS.2023.123753

Steps Toward Industry 5.0: Building “6S” Parallel Industries With Cyber-Physical-Social Intelligence

Xingxia Wang, Jing Yang, Yutong Wang, Qinghai Miao, Fei-Yue Wang, Aijun Zhao, Jian-Ling Deng, Lingxi Li, Xiaoxiang Na, Ljubo Vlacic

Abstract:Very recently, intensive discussions and studies on Industry 5.0 have sprung up and caused the attention of researchers, entrepreneurs, and policymakers from various sectors around the world. However, there is no consensus on why and what is Industry 5.0 yet. In this paper, we define Industry 5.0 from its philosophical and historical origin and evolution, emphasize its new thinking on virtual-real duality and human-machine interaction, and introduce its new theory and technology based on parallel intelligence (PI), artificial societies, computational experiments, and parallel execution (the ACP method), and cyber-physical-social systems (CPSS). Case studies and applications of Industry 5.0 over the last decade have been briefly summarized and analyzed with suggestions for its future development. We believe that Industry 5.0 of virtual-real interactive parallel industries has great potentials and is critical for building smart societies. Steps are outlined to ensure a roadmap that would lead to a smooth transition from CPS-based Industry 4.0 to CPSS-based Industry 5.0 for a better world which is Safe in physical spaces, Secure in cyberspaces, Sustainable in ecology, Sensitive in individual privacy and rights, Service for all, and Smartness of all.

Keywords: ACP, artificial intelligence, CPS, CPSS, Industry 4.0, Industry 5.0, parallel industries, parallel intelligence

I. Introduction

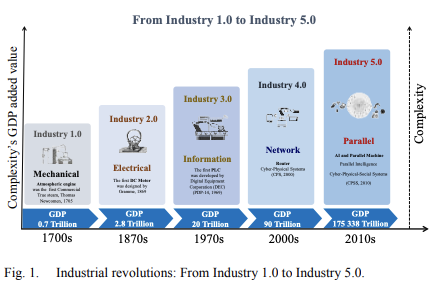

SINCE industry is the primary engine driving national economic growth, efforts to improve industrial production and efficiency never stop. The development of industrial automation and mechanization (as depicted in Fig. 1) has made most of traditional and tedious labors being conducted by machines. However, the wisdom and skills of humans, especially creative thinking and logical analysis, are still indispensable and crucial in industrial systems [1], an issue that goes beyond the current Industry 4.0 [2]. Therefore a step forward is necessary and needed. Industry 5.0 represents such a new and further development and improvement of Industry 4.0, which emphasizes interaction and cooperation between humans and machines, aiming at achieving enhanced productivity and innovation capability by combining the wisdom and creativity of humans with the precision and efficiency of machines [3]–[8].

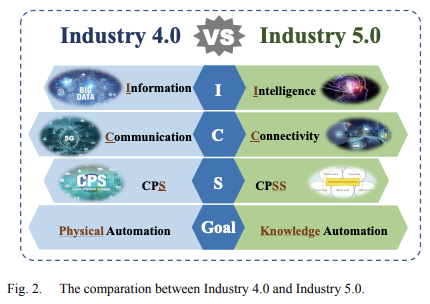

To promote the cooperation and interaction between humans and machines, Industry 5.0 is characterized by intelligence, connectivity, cyber-physocal-social systems (CPSS), and knowledge automation (see Fig. 2). In traditional Industry 4.0, information and communication technology (ICT) [9] as well as cyber-physical systems (CPS) are designed for inter-device communication and hardware system optimization. Compared to Industry 4.0, Industry 5.0 tries to liberate humans from physical and intellectual labor through Intelligence, facilitate deep communication and collaboration between humans and machines through Connectivity, and ultimately achieve Knowledge Automation.

Extensive research has been conducted on Industry 5.0 over the last two decades, especially the recent decade [10]–[17]. A recent notable effort is led by the European Union (EU) through the position document on Industry 5.0 [7] in 2021. Since 1999, Fei-Yue Wang and his team have been working on developing a theory with implementable frameworks and processes for Industry 5.0, where the core is parallel intelligence (PI) [18]–[20]. The ultimate goal of Industry 5.0 is to achieve knowledge automation by developing multiple tools for knowledge workers, and march towards the goal of realizing the “6S” world [21]. Since 2005, PI-based theory of Industry 5.0 has been implemented and verified in various fields, such as social computing [22], [23], complex chemical process [24], intelligent transportation systems [25], [26], parallel manufacturing [27], [28], smart agriculture [29], [30], parallel healthcare [31]–[34], parallel education [35]. This paper outlines the evolution of PI-based Industry 5.0 and explains its major method, technology, framework and process.

The remainder of this paper is organized as follows. The philosophical and historical origins of Industry 5.0 are introduced in Section II. Its main concepts and principles are presented in Section III. Key enabling technologies are outlined in Section IV. Major real-world applications are illustrated in Section V. Future trends are addressed in Section VI. Finally, concluding remarks are made in Section VII.

II. The Philosophical and Historical Origins

A. The Philosophical Origin

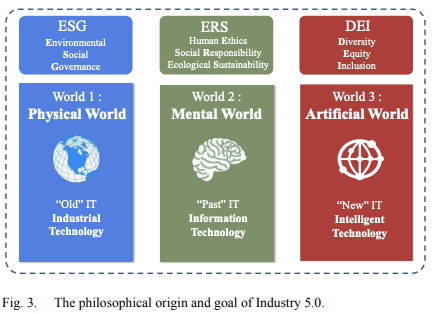

In his theory of parallel philosophy [36]–[38], Wang postulated that the philosophical origin of PI and Industry 5.0 is Platonic Idealism and Karl Popper’s Three Worlds theory of reality [38], along with Leibniz’s thinking on Monad [36], [37]. The philosophical struggle between idealism’s “way of truth” and materialism’s “way of opinion” and their unity of opposites lead to the philosophical foundation for parallel intelligence and related parallel industries. Popper’s three worlds provide the philosophical model to extend the “Two Bs” in traditional philosophy to the “Three Bs” in parallel philosophy, i.e., Being for Popper’s first world the physical world, Becoming of Popper’s second world the mental world, and Believing in Popper’s third world the artificial world.

For enriching the physical world, we had invented “Old IT”, the industrial technology; for flourishing the mental world, we had developed “Past IT”, the information technology; now we need to cultivate the artificial world, and we must build “New IT”, the intelligent technology, which would be the destination of Industry 5.0 and parallel industries [39].

Philosophical considerations offer a philosophical foundation for ensuring Industry 5.0 will be for a better world for humanity. From the very beginning, we must hold organizations and individuals accountable in ESG (environmental, social, governance), ERS (human ethics, social responsibility, ecological sustainability), DEI (diversity, equity, inclusion) related issues in dealing with three worlds (see Fig. 3), and prescribe a roadmap to “6S” world for PI and Industry 5.0.

B. The Historical Origin

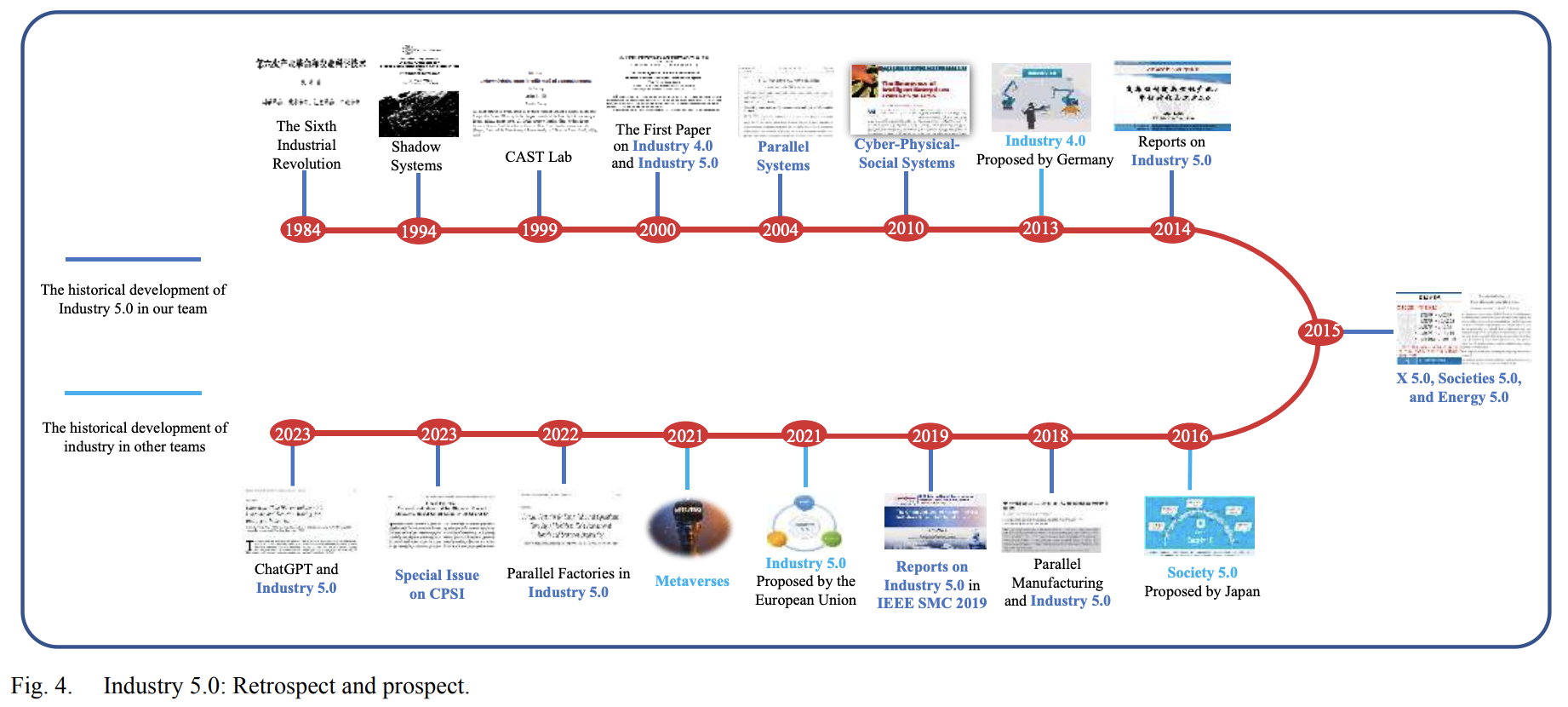

Over the past few decades, the terminology of Industry 5.0 has undergone a series of evolution, and its theory has been progressively developed and refined (as shown in Fig. 4).

In 1984, H.-S. Tsien predicted the emergence of Industry 6.0 [40]. Based on his previous research on shadow systems [41], Wang discussed the fifth industrial revolution in the report on CAST Lab [3], [4] in 1999, where cyber-social-physical (CSP) systems were presented. Originating from the report on the 1st China Appliance Science and Technology Conference in 2000, the first paper on the fourth industrial revolution and the fifth industrial revolution was released [42] in 2001, and it pointed out that smart technology and AI will enter individual families and the whole society, leading to the fifth industrial revolution. In 2004, Wang proposed parallel systems to solve social-related problems for complex systems [43] and provide theoretical support for the fifth industrial revolution. After considering the significant impact that social factors will have on industrial development, CPSS was proposed in 2010 [44] as a new form for CSP systems, which originated from the previously proposed CSP [3], [4]. In 2013, Germany proposed “Industrie 4.0” in Hannover Messe [2]. Compared with the CPS in Industry 4.0, CPSS can provide a more comprehensive framework and operation spaces for the fifth industrial revolution.

In 2014, Wang renamed parallel industry and the fifth industrial revolution to Industry 5.0 [5], [45], pointing out that Industry 5.0 equals Parallel 1.0, and made the effort to create and disseminate the message to the public that the future will be a parallel era of virtual-real interactions. From 2014 to 2015, Societies 5.0, Energy 5.0, Control 5.0, Systems 5.0, Transportation 5.0, and X 5.0 were proposed [46], [47]. In 2016, Japan proposed Society 5.0 [48]. In 2021, the EU released its report on Industry 5.0 [7]: Industry 5.0: Towards a sustainable, human-centric and resilient European industry. In the same year, metaverses [49] became one of the trending topics, where CPSS is regarded as its abstract and scientific name [19]. Over the last two decades, Wang’s team continues their research and development on Industry 5.0 which are widely reported in their publications [50]–[57].

III. Parallel Intelligence for Industry 5.0

A comprehensive introduction to PI-based Industry 5.0 is presented here by outlining its principles and frameworks for developing an innovative paradigm for industrial production that emphasizes the integration of advanced technologies, social factors, and sustainable development practices.

A. Principles of Industry 5.0

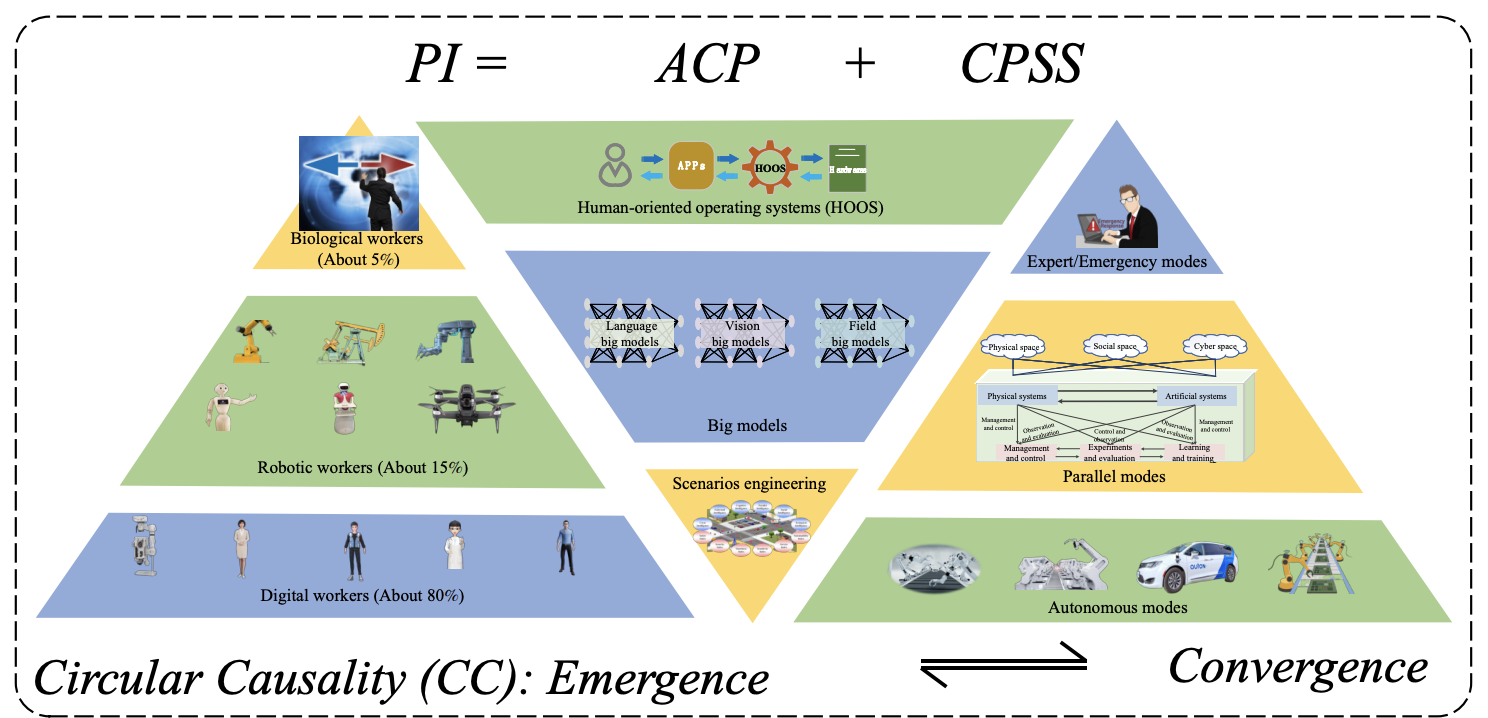

To materialize the blueprint of Industry 5.0, dedicated efforts must be made to establish knowledge workshops, develop knowledge tools, set up knowledge pipelines, and operate knowledge factories, aiming to empower knowledge workers at a unprecedent level. Therefore, three significant cornerstones that would make Industry 5.0 a reality are utilized (as demonstrated in Fig. 5), and each cornerstone consists of three key elements that will contribute significantly to the realization of Industry 5.0.

1) The first cornerstone includes big models [58]–[60], scenarios engineering (SE) [61], and human-oriented operating systems (HOOS) [62]. Compared with the existing feature engineering, SE can construct more trustworthy artificial systems, which will help build more interpretable and reliable industries. Benefiting from the rapid development of intelligent technologies, big models can not only offer systematic frameworks for industries but also facilitate the integration of diverse technologies into a cohesive system. Moreover, because social factors are an inevitable element in Industry 5.0, HOOS is designated to fully integrate social factors.

2) The second cornerstone is three types of workers in Industry 5.0: biological workers (approximately 5%), digital workers (approximately 80%), and robotic workers (approximately 15%). Among these workers, biological workers like us will serve as the leader and commanders of the whole industrial system. Digital workers have the ability to communicate with other workers and generate strategies for specific tasks. And robotic workers will operate in the physical world and execute given strategies. The joint effort among the proposed different workers will ultimately construct more intelligent and resilient organizations.

3) The third cornerstone is three kinds of operation modes: autonomous modes (AM, > 80%), parallel modes (PM, < 15%), and expert/emergency modes (EM, < 5%). In AM, the duty of biological workers is to monitor whether the system operates normally. If an anomaly occurs, the system will switch to PM, where biological workers will supervise and work with other workers remotely. However, if the problem can not be solved by PM, EM will be triggered. And related experts will be immediately dispatched to physical sites to solve knotty situations. After the anomaly is solved, the operation mode will gradually cascade to AM.

In summary, PI-based Industry 5.0 will achieve “small tasks, big models, and deep intelligence” through mutual cooperation and interaction among these three cornerstones.

B. The Basic Framework of Industry 5.0

To facilitate interactions and cooperation between humans and machines, we propose a basic framework (as shown in Fig. 6) with six layers: execution layer in physical spaces, communication layer for the transmission of generated data and delivered orders, data processing to obtain high-quality and accurate data, scenarios engineering for artificial systems, big models to execute computational experiments, and application layer for various social needs. These layers will cooperate to develop more reliable systems. For each layer, its main functions are provided in the following:

1) Execution Layer: For this layer, HOOS, various executing agents, and smart scenarios are the main components. To be specific, HOOS is designed to be more user-friendly and intuitive, creating a more seamless and efficient experience for biological workers. The interface in HOOS should allow biological workers to interact with the system in a natural and intuitive way. HOOS should also be responsive to various inputs, enabling users to customize settings and preferences to meet their individual needs. Also, various executing agents, such as robots, sensors, and UAVs, are corresponding implementing units for smart scenarios (such as Industries, Smart Homes, and Hospitals) in physical spaces.

2) Communication Layer: Based on the data generated in the execution layer, the major duty of this layer is to achieve fast and reliable data transmission. 5G is a wireless technology that enables high-speed data transmission over long distances and makes it ideal for connecting devices in remote locations. Ethernet, a wired technology, can facilitate communication among devices within a local area network (LAN). WIFI enables devices to connect to a LAN or the Internet without requiring physical cables, which is widely used in consumer devices such as Smart Homes and Internet of Things (IoT) applications. EtherCAT allows real-time communication among sensors, actuators, and other devices, and guarantees precise and synchronized control of complex systems. The introduction of these technologies ensures effective communication among devices and layers, providing a foundation for the development of advanced applications and services in Industry 5.0.

3) Data Processing: Once the communication layer has transmitted data to this layer, the next step is to process the obtained data. Therefore, this layer aims to manage, organize, and analyze large volumes of data. Firstly, data cleaning will be used to ensure the accuracy and reliability of the obtained data. Afterward, these multi-source data will be fused to gain additional information and insights. In the next, the fused data will be stored through various technologies. Finally, various analytical techniques will be utilized to extract knowledge and insights from the obtained data.

4) Scenarios Engineering: In Industry 5.0, descriptive intelligence, predictive intelligence, and prescriptive intelligence are the most important technologies. Based on the processed data and mathematical models, SE can serve as an effective tool to model artificial systems, which is defined as the integrated reflection of the scenarios and activities within a certain temporal and spatial range [63], [64]. For SE, its main components are intelligence and index (I&I), calibration and certification (C&C), and verification and validation (V&V). Through the integration of these main components, SE can provide useful guidance for the life-cycle of complex industrial systems and acquire appropriate model parameters after system testing, constructing more trustworthy and solid systems for Industry 5.0.

5) Big Models: Based on the model built by SE, the primary focus of this layer is to attain predictive intelligence and prescriptive intelligence. To accomplish this, a diverse range of large-scale models will be utilized. Algorithmic intelligence necessitates the use of numerous algorithms, while linguistic intelligence and graphical intelligence will be advanced through language and image models, respectively. Additionally, field big models like EuArtisan [51] will be implemented to address specific industrial scenarios. In the future, the development of imaginative big models will enable the generation of even more innovative products.

6) Application Layer: Incorporating social factors is a crucial and necessary aspect of PI-based Industry 5.0, particularly in this layer. It is essential to thoroughly consider human demands and requirements in order to meet the goals of managing factories, ensuring worker safety, delivering high-quality products, operating efficiently, and conserving energy. By specifying these high-level requirements, this complex system can be designed and constructed to realize the “6S” world, encompassing aspects such as safety, sustainability, satisfaction, productivity, quality, and energy efficiency.

IV. Key Technologies

A new decentralized ecosystem for Industry 5.0 is emerging. In this section, we first discuss DeSci (decentralized science) [65]–[67], DeEco (decentralized economies), and DeSoc (decentralized societies) needed by Industry 5.0, then introduce the key enabling technologies for implementing these decentralized systems, as depicted in Fig. 7.

A. Ecological Organizational Support: DeSci, DeEco, and DeSoc

Compared to centralized systems, decentralized systems imply increased security, privacy, transparency, and inclusiveness. The goal of DeSci is to establish a system that encourages researchers to share their findings and earn recognition for their work, while also enabling easy access and contribution to research by anyone. The underlying principle of DeSci is that scientific knowledge should be available to all, and the research process should be transparent. DeSci achieves decentralized access to funding, collaboration chances, laboratory services, and publishing channels. DeSci also enables intellectual property (IP) and peer-reviewing ownership. By adopting a decentralized and distributed research paradigm, DeSci aims to foster a transparent and democratic environment where innovative and unconventional ideas can thrive.

Similarly, DeEco and DeSoc aim to build decentralized economies and societies, where transactions and decisions are conducted through a distributed network of participants, rather than being controlled by a central authority such as corporations. Power is distributed among participants who interact with each other directly, and they set their own regulations without the need for intermediaries or middlemen.

B. Underlying Technological Support

To implement these transparent, democratic, and decentralized governance systems, DAOs (decentralized autonomous organizations and operations) [68], [69] is deployed and operated. In DAOs, members could submit proposals for consideration by the community. The proposals are then voted on by members using tokens that represent their stakes in the organization. The voting process is transparent and auditable, and decisions are made based on the outcome of the vote. And whether the proposal is approved or rejected is determined by the will of the majority. The DAOs is designed to be autonomous, which means it runs by rules encoded as computer programs called smart contracts, and operates on a blockchain network without the need for human intervention. These smart contracts define the organization’s purpose, membership rules, decision-making processes, and governance structures.

When a smart contract is executed, the transaction is recorded on the blockchain, creating a permanent and transparent record of the contract’s execution. Because the blockchain is decentralized and distributed, the record of the contract’s execution is replicated across the entire network, making it tamper-proof and resistant to fraud or manipulation. Blockchain technology [70]–[72] provides the underlying infrastructure for smart contracts. As a decentralized, digital ledger technology, blockchain works by using a network of nodes to maintain a shared database, which is constantly updated with new transactions. Specifically, data is organized into “blocks”, which are linked together in the chronological order to form a “chain”. Each block contains a unique digital signature, called a “hash”, that identifies it and all the data within it. When a new block is added to the chain, it is validated by the network of users through a consensus mechanism, such as proof-of-work or proof-of-stake. This ensures that the block is legitimate and that the data within it is accurate and unalterable. Once validated, the new block is added to the chain and becomes part of the permanent and transparent record of all transactions on the network. Because data is stored on many different computers across the blockchain network, it is extremely difficult to manipulate or hack. Any attempts to alter the data on the blockchain would require an attacker to simultaneously manipulate the data on a majority of the computers in the network, making it highly secure and resistant to fraud.

Overall, blockchain, smart contracts, and DAOs provide a powerful tool for creating decentralized, autonomous, and transparent governance structures for a wide range of industrial applications. By leveraging these technologies, we could enable greater community participation and decision-making in DeSci, DeEco, and DeSoc, while providing a secure and transparent platform for PI-based Industry 5.0.

V. Applications

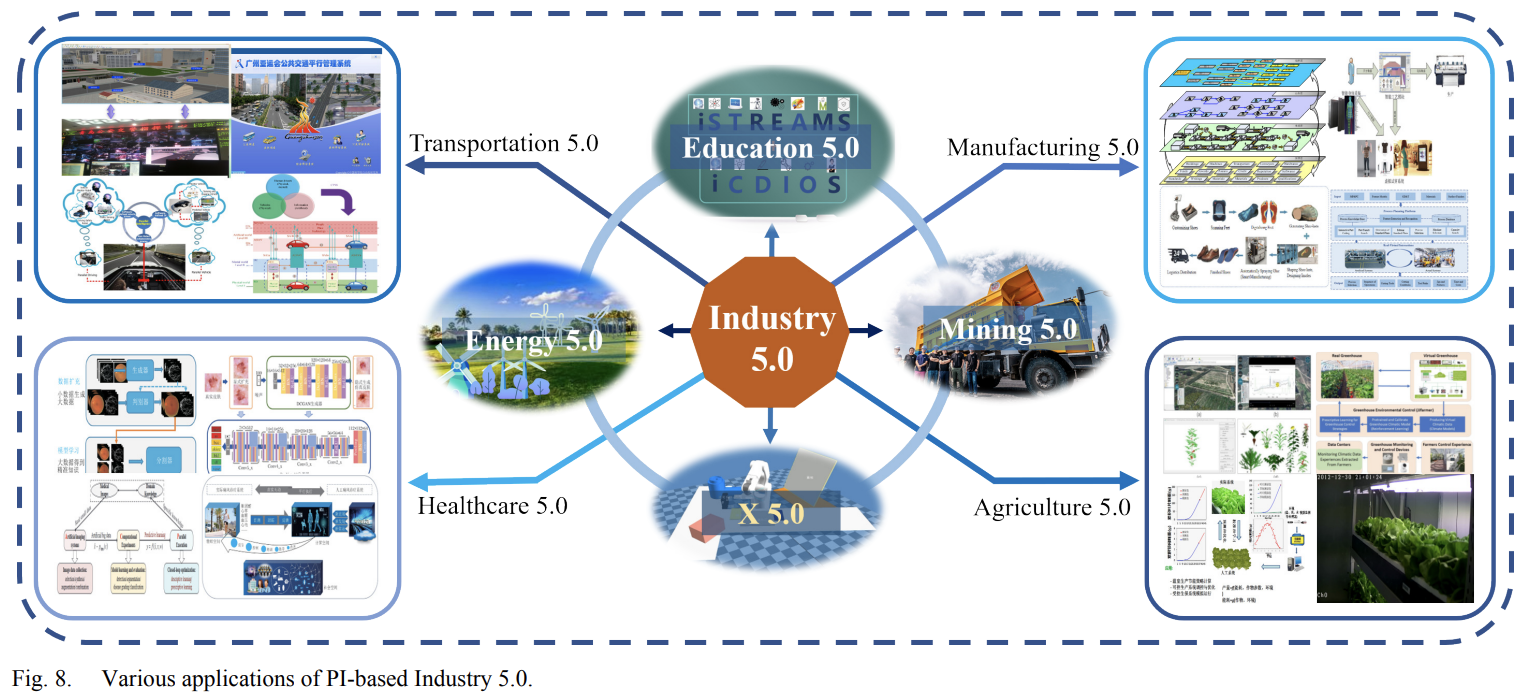

As illustrated in Fig. 8, the ACP approach and CPSS have been deeply explored and widely applied in various fields for the realization of Industry 5.0, such as transportation, manufacturing, healthcare, and agriculture. Consequently, this section presents some of its existing case studies.

A. Transportation 5.0

Transportation systems have undergone an evolutionary journey from Transportation 1.0 to Transportation 4.0, which has enabled the coordination of social transportation resources and the provision of efficient and convenient travel solutions to meet the basic needs of human mobility. However, current transportation systems are generally planned and managed by a centralized authority, and the public transportation demands are assumed to be relatively uniform. Hence, they are difficult to meet the diverse and varying needs of individuals and communities in a decentralized society form.

Transportation 5.0 [73], [74] is mainly characterized by decentralization and parallelization, focusing on employing cutting-edge technologies [75] such as artificial intelligence, blockchain, DAOs, and privacy-preserving computing, to mine and leverage distributed data for efficient allocation and management of decentralized transportation sources. DeCAST, a platform architecture of parallel transportation management and control through DAOs and the ACP approach, has been ingeniously designed and skillfully implemented in multiple Chinese cities including Guangzhou, Qingdao, Hangzhou, and Hefei [76]–[78]. It has demonstrated remarkable performance in the adaptation of varying human requirements as well as dynamic and complex traffic environments. Additionally, parallel driving [79], parallel sensing [60], and parallel vision [80] are considered important research directions, providing significant support for the realization of parallel transportation.

B. Manufacturing 5.0

As the most significant component of industrial sectors, manufacturing is a primary application area for advanced technologies like digital twins and IoT. Manufacturing 4.0, originating from Industry 4.0, aims at achieving full digitization and automation without human intervention in factories. Manufacturing 4.0 strives for full digitization and automation in factories without human intervention, while manufacturing 5.0 emphasizes the significant impacts of human factors on product production [27]. Manufacturing 5.0 can take great advantage of the thinking ability of human resources to meet the highly personalized needs of customers. From the perspective of Karl Popper’s three worlds, it is characterized by human-machine integration, knowledge-action emergence, and real-virtual convergence.

Parallel manufacturing can be regarded as an effective paradigm for the realization of manufacturing 5.0. In parallel manufacturing [27], [28], [65], [81], social intelligence is collected, analyzed, and extracted to meet social demands by employing knowledge automation, social computing, and artificial intelligence. And collective wisdom is gathered to conduct product R&D via crowdsourcing. With the help of parallel machines [82], parallel energy [83], and parallel unmanned systems [84], [85], digital workers and robotic workers constantly perform the majority of the routine physical and intellectual loads instead of using biological workers. Double closed-loop feedback, virtual-real co-evolution, and collaborative optimization of a series of manufacturing processes are efficiently achieved through the construction of parallel manufacturing systems.

C. Healthcare 5.0

As intelligent technologies are increasingly applied to medical systems for assisting doctors in their treatments, the healthcare industry has entered the era of Healthcare 4.0, where a human-machine division has been achieved to some extent. However, the current healthcare systems are still facing some challenges, such as over-reliance on doctors’ experience, tense doctor-patient relationships, insufficient data, and poor interpretability [86]. Consequently, Healthcare 5.0 must be developed to deal with these important issues, moving toward scientific, humanistic, and social medicine.

To this end, parallel healthcare systems model the static and dynamic features of doctors and patients, test and evaluate the applicability and effectiveness of various therapeutic regimens, and then prescript robotic or human doctors to implement the treatment [33], [87]. In these systems, three types of doctors (i.e., digital doctors, robotic doctors, and biological doctors) coexist, leading to a shift in the paradigm of diagnosis and treatment to a virtual-real division [88]. The core of Healthcare 5.0 is real-virtual interaction, which promises to fundamentally transcend limitations in geography and individual capabilities [33], [34]. In other words, people in different regions can enjoy almost equal access to medical resources. Specifically, parallel skin [89], parallel gout [90], parallel eyes [91], and parallel gastrointestine [92] have been proposed to achieve parallel diagnosis and treatment of diseases.

D. Agriculture 5.0

The ever-expanding global human population and the pressing issue of climate change make it imperative to prioritize the development of sustainable agriculture. Agriculture 4.0 integrates advanced technologies such as IoT, robotics, artificial intelligence, and big data, promoting greater automation and intelligence in agricultural production. However, with the deep fusion of CPSS, human and social factors must be fully considered to achieve sustainability, resiliency, and flexibility of production [93], which goes far beyond the scope of Agriculture 4.0 and belongs to the focus of Agriculture 5.0.

Since Wang built the “virtual or shadow plant” in the 1990s, a series of works have been accomplished, including complex adaptive systems for smart agriculture (CASA), distributed CASA (DiCASA) and decentralized CASA (DeCASA) [29], [30], [94], [95]. These works can facilitate the transformation of the agricultural paradigm from human and animal-powered traditional agriculture to autonomous and intelligent “6S” parallel agriculture. DeCASA simulates and optimizes the dynamic processes related to agricultural production, environments, and management activities around the production chain using the real-virtual interactions of physical and artificial systems. As a result, it has the potential to become a primary model of Agriculture 5.0.

VI. Future Trends

A. From Algorithmic Intelligence to Linguistic Intelligence and Then to Imaginative Intelligence

As stated in [96], the research and development of artificial intelligence can be divided into three levels of intelligence and ranked from low to high as follows: 1) algorithmic intelligence (AI), 2) linguistic intelligence (LI), and 3) imaginative intelligence (II). AI refers to the ability of a computer program or system to solve specific problems through algorithms and mathematical models, helping to liberate humans from tedious and repetitive tasks. However, algorithms are not capable of modeling every problem described in natural language, so it is imperative and essential to realize LI. With its powerful capabilities in natural language understanding and generation, ChatGPT has heralded a new era of LI and holds the promise of providing a more convenient way for human-machine interaction and coordination. However, the key issue in achieving true LI is how to ensure that ChatGPT-like language foundation models’ responses are consistent with the facts. Visual information such as images and videos cover a wider range of expression than natural language. II needs to be developed to comprehend human intentions by visual means and draw more concrete blueprints for the future. Finally, AI, LI, and II will empower digital and robotic humans for accurate, trustworthy, and efficient decision-making and operational execution, allowing biological workers to concentrate on more creative and complex tasks.

B. From Professional Division to Human-Machine Division and Then to Virtual-Real Division

The professional division is a mainstream method of organization and management in most fields, which allocates each relatively independent component of a task to personnel with high-level expertise, specific experience, and knowledge. With the development of intelligent technologies, the increasing involvement of machines in industrial production has led to a reduction in the workload for humans, and the social division of labor is gradually moving towards human-machine division. Human-machine division puts a greater emphasis on interactions and collaborations between individuals and equipment, so it is crucial to make use of interface technology such as augmented reality (AR), vritual reality (VR), and mixed reality (MR). With further advancement of machine intelligence and the emergence of big models, physical and artificial machines are progressively taking over occupations that humans used to do. In other words, robotic and digital workers will undertake almost all the physical and intellectual workloads. Therefore, the virtual-real division will hold a dominant position in the future, and digital twins, PI, as well as metaverses must be effectively applied.

VII. Conclusion

The development of advanced technologies has led to the integration of engineering systems with social systems, attracting increasing attention to Industry 5.0, especially raising awareness about the crucial role of human within systems. Industry 5.0 is built upon the CPSS infrastructure and adopts parallel industries as its core concept. Based on ACP approach and PI, it can effectively achieve the parallel management and control of complex systems that involve social factors. And its key elements are three cornerstones (SE, big models, and HOOS), three types of workers (biological workers, digital workers, and robotic workers), and three operation modes (AM, PM, and EM), with three cornerstones driving the work of three types of workers under three modes. Blockchain, smart contracts, and DAOs can enable the construction of unique ecosystems (e.g., DeSci, DeSoc, and DeEco) in Industry 5.0, facilitating their distributed, autonomous, and transparent management. Through applications in various fields, such as transportation, manufacturing, healthcare, and agriculture, PI-based Industry 5.0 has demonstrated excellent performance in adapting to varying human requirements and complex dynamic environments. Therefore, we believe the implementation of Industry 5.0 will better coordinate human-machine relationships and encourage the progress from LI to II, prompting us to move forward to a “6S” world.

参考文献:

https://blog.sciencenet.cn/blog-2374-1397717.html

上一篇:[转载]【CAA期刊】《中国自动化学会通讯》2023年第7期发布!

下一篇:[转载]IEEE TCSS 第10卷4期网刊已发布, 敬请关注!