博文

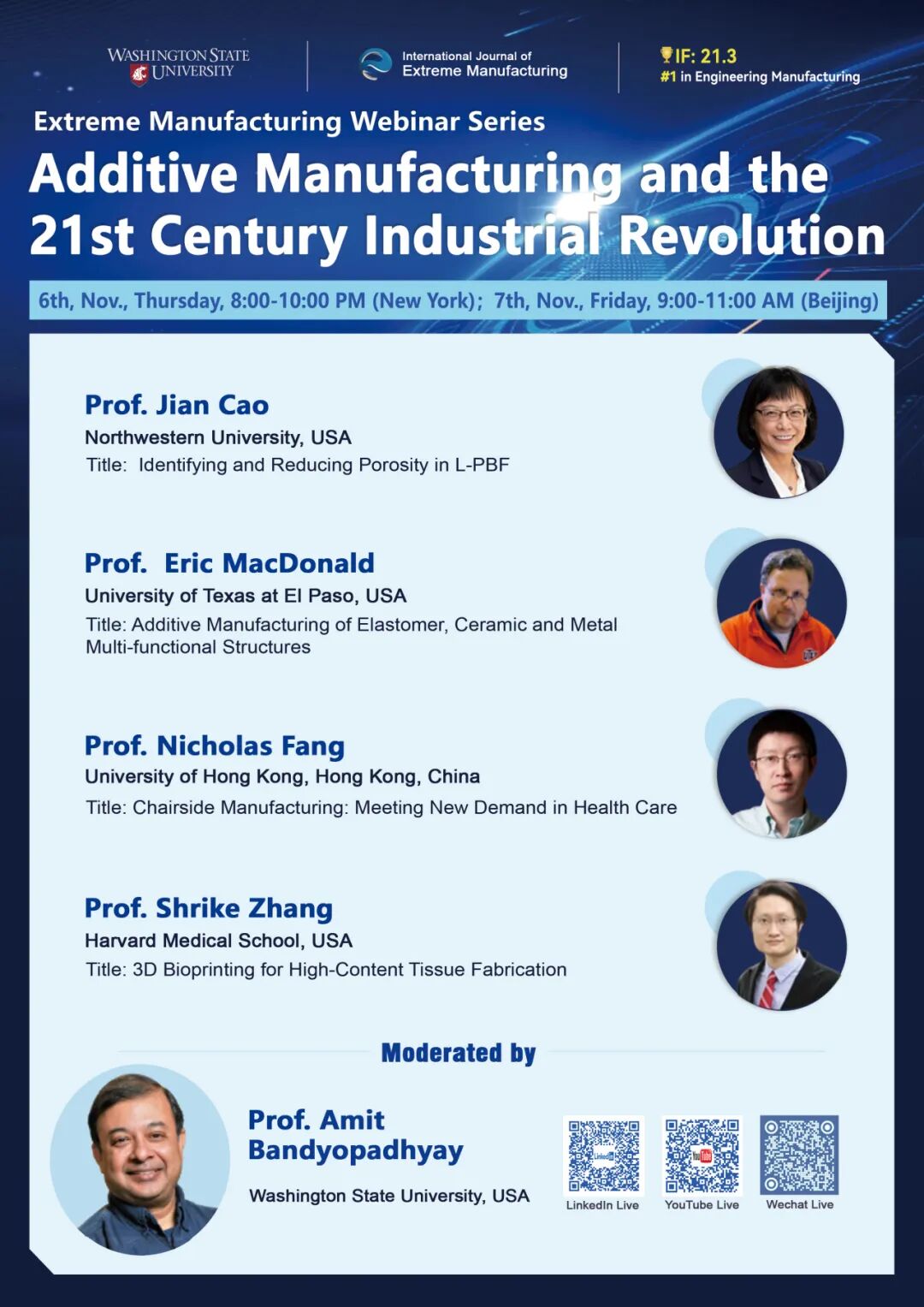

“增材制造与21世纪工业革命”在线论坛

||

论坛主题

“增材制造与21世纪工业革命”在线论坛

形式及时间

线上,2025年11月7日(周五)

北京时间 上午9:00-11:00

举办单位

主办:华盛顿州立大学

支持:《极端制造(英文)》期刊

主持人

2025.11.07

Amit Bandyopadhyay

Washington State University, USA

个人简介

Amit Bandyopadhyay is a Boeing Distinguished Chair Professor in the School of Mechanical and Materials Engineering and an Affiliate Professor of the College of Medicine at Washington State University (WSU). His research expertise focuses on additive manufacturing / 3D Printing, emphasizing bone implants and multi-material structures. He has worked with 25 Ph.D. and 35 MS graduate students, several post-doctoral research associates, visiting faculty members, and over 50 undergraduate students at WSU. He has written over 400 technical articles, edited 12 books, is an inventor of 21 issued patents, and is a member of several journals' editorial boards.

He received the CAREER award from the National Science Foundation and the Young Investigator Award from the Office of Naval Research. He is a Fellow of the Materials Research Society (MRS), American Ceramic Society, American Society for Materials, American Institute for Medical and Biological Engineering, American Association for the Advancement of Science, National Academy of Inventors, Society of Manufacturing Engineers, and an elected member at the Washington State Academy of Science. His work has been cited over 45,500 times, and the current "h" index is 109 (Google Scholar).

报告简介

2025.11.07

Jian Cao

Northwestern University, USA

报告题目

Identifying and Reducing Porosity in L-PBF

报告摘要

In this talk, I will demonstrate our work in the development of differentiable simulation tools, sensing, and process control to achieve effective and efficient predictions and control of mechanical behavior in metal additive processes. Furthermore, I will show how we use machine learning to accelerate the physics-based simulations and to realize active sensing with the goal of effective in-situ local process control. Our solutions particularly target three notoriously challenging aspects of the process: long history-dependent properties, complex geometric features, and the high dimensionality of their design space.

个人简介

Cardiss Collins Professor Jian Cao (MIT’Ph.D, MIT’MS, SJTU’BS) specialized in innovative manufacturing processes and systems, particularly in the areas of deformation-based processes and laser additive manufacturing processes. She is the Founding Director of the research center on Manufacturing Science and Innovation at Northwestern, known as NIMSI.

Prof. Cao is an elected member of the National Academy of Engineering (NAE) and of the American Academy of Arts and Sciences (AAA&S). Her major awards include DoD Vannevar Bush Faculty Fellowship, ASME Ted Belytschko Applied Mechanics Award, the inaugural ASME Devor-Kapoor Manufacturing Medal, Hideo Hanafusa Outstanding Investigator Award for Flexible Automation, ASME Milton C. Shaw Manufacturing Research Medal, Charles Russ Richards Memorial Award from ASME and Pi Tau Sigma, SME Gold Medal, and SME Frederick W. Taylor Research Medal. Cao was the Editor-in-Chief of Journal of Materials Processing Technology.

Prof. Cao now serves as an Associate Vice President for Research at Northwestern, a member of the National Materials and Manufacturing Board of the National Academies, a member of the Defense Materials, Manufacturing and its Infrastructure (DMMI) Standing Committee of the National Academies, Board of Directors of SME, and Board of mHUB – accelerator for hardtech innovation and manufacturing in Chicago.

Eric MacDonald

University of Texas at El Paso, USA

报告题目

Additive Manufacturing of Elastomer, Ceramic and Metal Multi-functional Structures

报告摘要

3D printing has been historically relegated to fabricating conceptual models and prototypes; however, increasingly, research is now focusing on fabricating functional end-use products. As patents for 3D printing expire, new low-cost desktop systems are being adopted more widely and this trend is leading to a diversity of new products, processes and available materials. However, currently the technology is generally confined to fabricating single material static structures. For additively manufactured products to be economically meaningful, additional functionalities are required to be incorporated in terms of electronic, electromechanical, electromagnetic, thermodynamic, chemical and optical content. By interrupting the 3D printing and employing complementary manufacturing processes, additional functional content can be included in mass-customized structures. This presentation will review work in multi-process 3D printing for creating structures with consumer-anatomy-specific wearable electronics, electromechanical actuation, electromagnetics, energy storage, propulsion, embedded sensors in soft tooling – in polymers, elastomers, metal and ceramic material systems.

个人简介

Eric MacDonald, Ph.D. is a professor of aerospace and mechanical engineering and Murchison Chair at the University of Texas at El Paso and serves as the Associate Dean of Research and Graduate Studies for the College of Engineering. Dr. MacDonald received his doctoral degree (2002) in Electrical and Computer Engineering from the University of Texas at Austin. He worked in industry for 12 years at IBM and Motorola and subsequently co-founded a start-up specializing in CAD software and the startup was acquired by a firm in Silicon Valley.

Dr. MacDonald held faculty fellowships at NASA’s Jet Propulsion Laboratory, US Navy Research and was awarded a US State Department Fulbright Fellowship in South America. His research interests include 3D printed multi-functional applications and process monitoring in additive manufacturing with instrumentation and computer vision for improved quality and yield. As a co-founding editor of the Elsevier journal Additive Manufacturing, MacDonald has helped direct the academic journal to have highest impact factor among all manufacturing journals worldwide. He has recently been involved in the commissioning of a second partner journal, Additive Manufacturing Letters, upon which he serves as the Editor-in-Chief.

Recent projects include 3D printing of structures such as nano satellites with structurally-embedded electronics - one of which was launched into Low Earth Orbit in 2013 and a replica of which was on display at the London Museum of Science. He has over 100 peer-reviewed publications, dozens of patents, one of which was licensed by Sony and Toshiba from IBM. He is a member of ASME, ASEE, senior member of IEEE and a registered Professional Engineer in the USA state of Texas.

Nicholas Fang

University of Hong Kong, Hong Kong, China

报告题目

Chairside Manufacturing: Meeting New Demand in Health Care

报告摘要

How is advanced manufacturing poised to unlock the next generation of personalized therapeutic and diagnostic tools? In this online talk, we discuss our research effort on advanced bioprinting towards integrating multifunctional, biocompatible materials. A central challenge lies in economically producing high-precision, patient-specific medical devices with rapid delivery times. As a case study, we show our recent interdisciplinary collaboration with dental material scientists to offer mass produced dental veneers with a streamlined production workflow at chairside, and a specialized finishing process to deliver less invasive restoration options. Finally, we will look beyond current applications and discuss emerging trends such as organ-on-a-chip systems and advanced human-machine interfaces.

个人简介

Professor Fang is currently Chair Professor of Photonics Innovation and Co-Director of Central User Facilities at the University of Hong Kong. Before joining HKU, Fang served on the faculty at the Massachusetts Institute of Technology and the University of Illinois at Urbana-Champaign. His research spans micro- and nanotechnology, focusing on scalable manufacturing techniques for wave-functional materials and devices. Fang’s innovations in energy conversion, optical communication, and biomedical imaging have led to over 16 patent applications in nano- and micro-fabrication, additive manufacturing, and imaging technologies.

His service to the society include the Associate Editor of the journals Microsystems & Nanoengineering (Springer Nature), National Science Review (Oxford Academic), PhotoniX (Springer), and International Journal of Extreme Manufacturing (IOP). He received the Best Editor Award 2024 from the International Journal of Extreme Manufacturing (the #1 ranking in the Engineering, Manufacturing category).

His professional recognition also includes: Fellow of the Society of Engineering Sciences; Fellow of the Optical Society of America; the Brillouin Medal from the International Phononics Society; the ASME Chao and Trigger Young Manufacturing Engineer Award; the Ernst Abbe Medal from the International Commission of Optics, the National Science Foundation CAREER Award, and inclusion in the MIT Technology Review's “35 Innovators Under 35”.

Y. Shrike Zhang

Harvard Medical School, USA

报告题目

3D Bioprinting for High-Content Tissue Fabrication

报告摘要

Over the last decades, the fabrication of three-dimensional (3D) tissues has become commonplace. However, conventional 3D fabrication techniques are limited in their capacity to produce complex tissue constructs with the required precision and controllability that is needed to replicate biologically relevant tissues. To this end, 3D bioprinting offers great versatility in the fabrication of biomimetic volumetric tissues that are structurally and functionally relevant. It enables precise control of the composition, spatial distribution, and architecture of bioprinted constructs facilitating the recapitulation of the delicate shapes and structures of targeted organs and tissues. This presentation will focus on discussing our recent efforts in developing a series of advanced 3D bioprinting strategies primarily from the technological perspective. These platform technologies will likely provide new opportunities in constructing functional tissues to facilitate regeneration as well as microtissue models for promoting personalizable medicine.

关于期刊

International Journal of Extreme Manufacturing (《极端制造》),简称IJEM,中国机械工程学会极端制造分会会刊,致力于发表极端制造领域相关的高质量最新研究成果。自2019年创刊至今,期刊陆续被SCIE、EI、Scopus等20余个国际数据库收录。JCR最新影响因子21.3,位列工程/制造学科领域第一。中国科学院分区工程技术1区,TOP期刊。入选中国科技期刊卓越行动计划二期英文领军期刊。

期刊网址:

https://iopscience.iop.org/journal/2631-7990

期刊投稿:

https://mc04.manuscriptcentral.com/ijem-caep

https://blog.sciencenet.cn/blog-3563286-1509037.html

上一篇:极端制造 | 3D打印有机水凝胶应变传感器的结构优化策略:实现高灵敏度与高稳定性

下一篇:科研速递| 高熵固废基胶凝材料的制备、性能与水化机理