博文

大规模生产微纤维的新方法

||

大规模生产微纤维的新方法

诸平

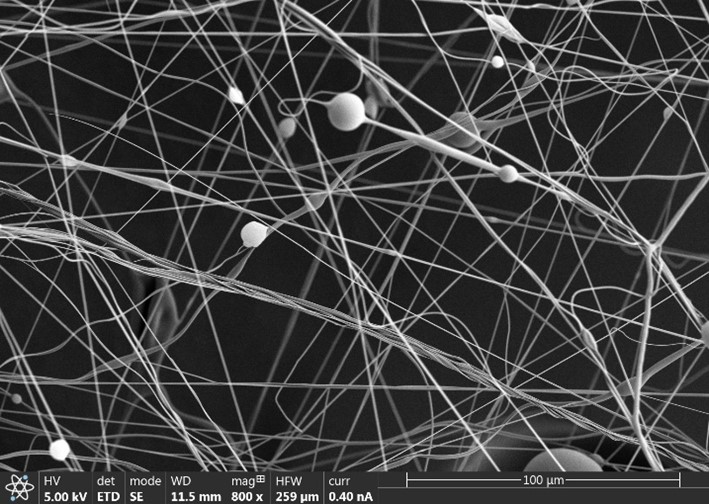

PVA 微纤维的电子显微镜图像(Imágenes de microscopio electrónico de microfibras de PVA)。

据塞维利亚大学(University of Sevilla / Universidad de Sevilla)2023年9月15日提供的消息,塞维利亚大学高等技术工程学院航空航天工程和流体力学系(Departamento de Ingeniería Aeroespacial y Mecánica de Fluidos de la Escuela Técnica Superior de Ingeniería de la Universidad de Sevilla)的教授们,发现了一种大规模生产微纤维的方法(New method for mass production of microfibers)。其旨在彻底改变传统方法,因为它将具有多种用途的微纤维的产量增加一千倍。

塞维利亚大学高等技术工程学院航空航天工程和流体力学系(Department of Aerospace Engineering and Fluid Mechanics of the School of Engineering of the University of Seville)的教授们实现了一种大规模生产微纤维(非常细的纤维)的方法,这种纤维有多种用途,例如,它们可用于制造口罩和个人防护装备(Personal Protective Equipments简称PPEs),再生组织,用于能量产生和存储系统或所谓的“智能组织”。这一发现旨在彻底改变传统方法,因为它使用的技术效率更高,可以将产量增加一千倍。

相关研究结果于2023年6月20日已经在英国皇家化学学会(Royal Society of Chemistry)主办的《RSC进展》(RSC Advances)杂志网站发表——Jesús Olmedo-Pradas, Alfonso M. Gañán-Calvo, Luis B. Modesto-López. Integrating a micro-mixing mechanism and on-line thermal processing for the large-scale ejection of polymeric liquid threads for producing ultrafine fibers. RSC Advances, Issue 27, 2023, First published: 20 Jun 2023. https://pubs.rsc.org/en/content/articlelanding/2023/RA/D3RA03070A

这项工作的相关性在于大规模工业化生产由聚乙烯醇 (polyvinyl alcohol简称PVA) 聚合物制成的纳米纤维。这些微纤维的直径小于1 μm,也就是说,它们可以像冠状病毒一样细,因为它比人的头发(100 μm)细100倍,比红细胞(8 μm)小8倍。

简单但稳健的技术(Simple but robust technology)

该研究旨在开发一种简单但稳健的技术,使用气动注射器生产微米和纳米纤维,该注射器采用液体喷涂工艺,类似于露台洒水器(terrace sprinklers)产生的工艺。

路易斯·莫德斯托·洛佩兹(Luis Modesto López)教授和阿方索·迦南·卡尔沃(Alfonso Gañán Calvo)教授以及学生赫苏斯·奥尔梅多·普拉达斯(Jesús Olmedo Pradas)发表了有关这项新技术的文章。路易斯·莫德斯托·洛佩斯解释说:“这项研究始于喷雾测试,旨在产生微滴。然而,相反,我们得到了我们称之为韧带(ligaments)的细长结构。我们认识到此韧带是通过使用具有一定粘弹性的高粘性液体形成的。“我们转向热源,进行喷雾,热量使韧带快速干燥,导致微纤维在几秒钟内形成。”

更高效(More efficient)

专家们声称,这项技术比现有方法更节能,因为它不依赖外部能源来破碎液体,而是“利用气流中包含的机械能来生成新的表面,即多种更细的韧带。”

该项目开辟了与由两种或多种聚合物材料组成的复合纤维制造相关材料的新研究领域。该研究得到了安达卢西亚研究、开发和创新计划 ( Andalusian Plan for Research, Development and Innovation简称PAIDI 2020) 计划和欧洲FEDER基金(European FEDER funds)的资助。

上述介绍,仅供参考。欲了解更多信息,敬请注意浏览原文或者相关报道。

Micro/nanofibers are structures that nowadays have a wide range of cutting-edge applications including energy generation and storage devices, smart textiles, cell growth, and tissue engineering. These fibrous materials are mostly produced from polymer solutions spun, under laminar flow conditions, into nanofibers by external forces. However, the turbulent interaction of gas–liquid interfaces offers an innovative approach for the high-throughput production of nanofibers. Here, we present Flow Blurring (FB), a solely pneumatic approach for the massive production of liquid threads of polymer solutions, which relies on a micro-mixing mechanism that triggers a turbulent motion capable of fragmenting a viscous flow. The as-ejected threads are subsequently processed thermally, on-line in a single-step, thus producing micro/nanofibers that form mats. The method operates with relatively large liquid flow rates, equivalent of a high production rate, and is thus suitable for industrial production of engineered nanomaterials. In this work, we used solutions of poly(vinyl alcohol) (PVA) to study its ejection and fragmentation dynamics through computational fluid dynamics (CFD) simulations. In addition, the physics underlying the regulation of the liquid flow rate in FB atomizers are proposed. Fibers with typical diameters in the range 400–800 nm were produced by online heating of the liquid threads. Liquid ejection experiments were performed under different operating conditions thus verifying the capability of the method for synthesizing submicrometer-sized fibers with high uniformity and production rates suitable for scaling up.

https://blog.sciencenet.cn/blog-212210-1402836.html

上一篇:美国宇航局将公布期待已久的UFO报告

下一篇:进化将人类的大脑连接起来,就像超级计算机一样