博文

镁合金腐蚀研究进展(25)—镁合金水滑石/硅烷/CeO2涂层耐蚀性研究

|||

镁合金腐蚀研究进展(25)—镁合金水滑石/硅烷/CeO2涂层耐蚀性研究

镁合金在航空、汽车、电子、航空航天等领域的有着广泛的应用前景,但是镁合金的易腐蚀性限制了其应用。表面改性处理是提高镁合金耐蚀性能的有效途径之一。

水滑石(layered double hydroxide, LDH)属于阴离子插层型层状化合物,层间阴离子具有可交换性,其组成和结构是可调的【1,2】。镁合金表面LDH膜包括钼酸盐系、Mg-Al系、Zn-Al系、Zn-Al-V系等【1-12】。虽然LDH膜内层比较致密,但是外层疏松多孔。这些孔隙为外界腐蚀介质渗入基体,同时也为镁基体腐蚀所产生的镁和氢氧根离子的渗出提供了通道。其结构特点降低了其长期耐蚀性。而LDH表面封孔处理对进一步提高镁合金的耐蚀性能或许有帮助【3】。

我们【4】曾采用聚乳酸(poly(lactic acid),PLA)涂层覆盖AZ31镁合金Zn-Al-LDH涂层,其耐蚀性能得到明显的提高。另外,我们也用低表面能硬脂酸(Steric acid, SA)修饰AZ31表面共沉积和水热处理制备的Mg(OH)2/Mg-Al-LDH涂层,获得超疏水的耐蚀性能优异的复合涂层【5】。Zhang等【6】用低表面能的全氟辛基三乙氧基硅烷(PFOTES, CF3(CF2)5CH2CH2Si(OCH2CH3)3)修饰AZ80镁合金表面 Mg-Al LDH 涂层。这种基于Cassie模型的超疏水表面为镁合金提供了长久的耐蚀性能。这是因为空气被捕获在表面微结构中。

我们【7】曾利用聚甲基三乙氧基硅烷(polymethyltrimethoxysilane, PMTMS)和硝酸铈(Ce(NO3)3)来封闭镁合金AZ31表面Mg(OH)2膜,制备了Mg(OH)2/PMTMS/CeO2复合涂层。CeO2作为物理屏蔽层,既影响了表面形貌,也减少了涂层的微孔和微裂纹。此涂层显示优异的耐蚀性能。

如果将具有缓蚀性的无机盐(如硝酸铈)与硅烷PMTMS复合涂层覆盖在LDH表面,封闭LDH孔隙以降低孔隙率,或许会形成致密和良好结合力的复合涂层。其耐蚀性能会得到显著提高。

本文首先运用共沉淀-水热合成法在AZ31基体表面制备出Mg-Al-CO32-水滑石,然后又使用PMTMS对水滑石涂层进一步改性,得到了一个耐蚀性好、超疏水和自修复等优良特性的水滑石/聚硅氧烷涂层。

另外,在这种复合涂层体系中又引入了稀土元素化合物。具体来说,就是在PMTMS硅烷溶液中溶解不同浓度(0, 10-4, 10-3, 10-2 M)的Ce(NO3)3,结果发现微量的Ce(NO3)3加入,使得复合涂层耐蚀性大大提高。有趣地是,当Ce(NO3)3含量增加到一定量(10-2 M)之后,耐蚀性反而下降,表面的形貌不再致密,能够清晰地看到内部的水滑石形貌。因此,适度掺杂Ce(NO3)3才可以提高这种复合涂层耐蚀性能。

该项工作“Corrosion resistance of a ceria/polymethyltrimethoxysilane modified Mg-Al-layered double hydroxide on AZ31 magnesium alloy”近日发表在Journal of Alloys and Compounds(764,2018:913–928)。研究生姚青松作为第一作者,通讯作者为张芬副教授和曾荣昌教授。

Fig. 1 FE-SEM images and CA pictures (inset) of LDH coatings (a, f), PMTMS coatings (b, g), PMTMS/CeO2-1 coatings (c, h), PMTMS/CeO2-2 coatings (d, i) and PMTMS/CeO2-3 coatings (e, j) and (k) cross-sectional microstructure and corresponding elemental mapping images of PMTMS/CeO2-2 coating.

Fig. 2 XPS survey scan of (a) PMTMS/CeO2-2 coating, (b) Mg 2p peaks, (c) C 1s peaks, (d) O 1s peaks, (e) Si peaks and (f) Ce 3d peaks.

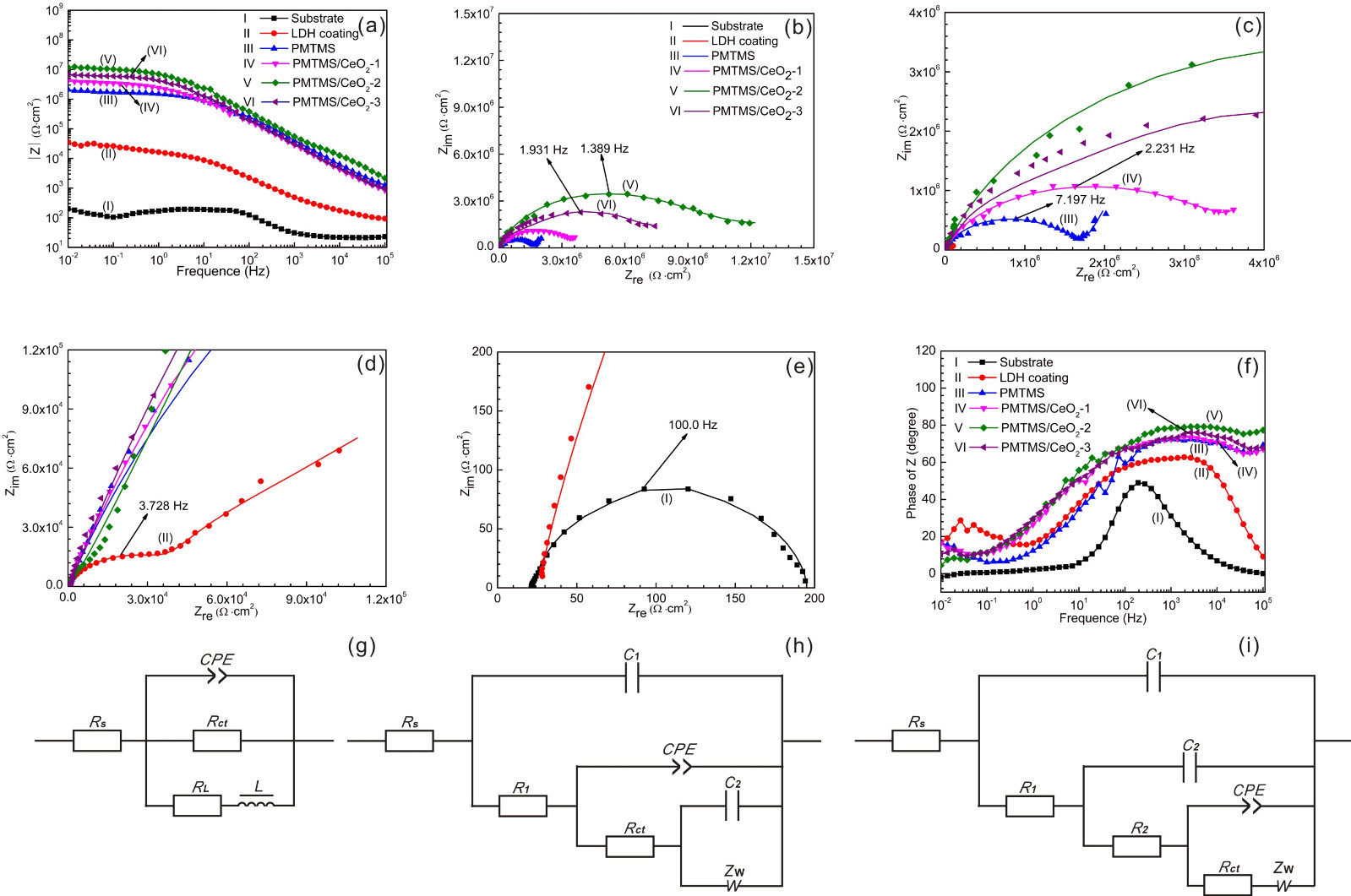

Fig. 6 EIS of (I) substrate, (II) LDH coating, (III) PMTMS coating, (IV) PMTMS/CeO2-1 coating, (V) PMTMS/CeO2-2 coating and (VI) PMTMS/CeO2-3 coating: (a) Bode plots of ׀Z׀ vs. frequency, (b) Nyquist plots and (c, d and e) enlarged Nyquist plots, (f) Bode plots of phase angle vs. frequency in 3.5 wt.% NaCl solution; equivalent circuits of (g) AZ31 substrate, (h) LDH coating, (i) PMTMS coating and PMTMS/CeO2 coatings.

相关链接:

科学网博客:

2. 镁合金腐蚀研究进展(7)—镁合金碳酸根镁铝水滑石涂层

3. 镁合金腐蚀研究进展(10)—镁合金表面镁铝水滑石转化膜进展

相关镁合金LDH论文:

[1] Corrosion of molybdate intercalated hydrotalcite coating on AZ31Mg alloy. Rong-Chang Zeng*, Zhen-Guo Liu, Fen Zhang, Shuo-Qi Li, Hong-Zhi Cui, En-Hou Han. Journal of Materials Chemistry A, 2014, 2,13049–13057.

[2] Corrosion resistance of Mg-Al-LDH coating on magnesium alloyAZ31. Fen Zhang, Zhen-Guo Liu, Rong-Chang Zeng*, Shuo-Qi Li, Hong-Zhi Cui, Liang Song, En-Hou Han. Surface & Coatings Technology, 258, 2014, 1152–1158

[3] Layered double hydroxide coatings on magnesium alloys: a review. Lian Guo, Wei Wu, Yong-Feng Zhou, Fen Zhang*, Rong-Chang Zeng**, Jianmin Zeng. Journal of Mateials Science and Technology. https://doi.org/10.1016/j.jmst.2018.03.003.

[4] Corrosion resistance of Zn-Al layered doublehydroxide/poly(lactic acid) composite coating on magnesium alloy AZ31. Rongchang Zeng*, Xiao-Ting Li, Zhen-Guo Liu, Fen Zhang, Shuo-Qi Li, Hong-Zhi Cui . Frontiers of Materials Science, 2015, 9(4): 355–365.

[5] Corrosion Resistance of the Superhydrophobic Mg(OH)2/Mg-Al Layered Double Hydroxide Coatings on Magnesium Alloys. Fen Zhang, Changlei Zhang, Rongchang Zeng*, Liang Song, Lian Guo, Xiaowen Huang. Metals, 2016, 6,85.

[6] Mitigation of Corrosion on Magnesium Alloy by Predesigned Surface Corrosion. X. Zhang, G. Wu, X. Peng, L. Li, H. Feng, B. Gao, K. Huo, P.K. Chu, Sci. Rep. 5(2015) 17399.

[7] Corrosion resistance of ceria/polymethyltrimethoxysilane modified magnesium hydroxide coating on AZ31 magnesium alloy. Lian Guo, Fen Zhang, Liang Song, Rong-Chang Zeng, Shuoqi Li, Enhou Han. Surface and Coatings Technology, 2017, 328: 121-133.

[8] A comparison of corrosion resistance of magnesium aluminum and zinc aluminum vanadate intercalated layered double hydroxides on magnesium alloys, Lian Guo, Fen Zhang, Jun-Cai Lu, Rong-Chang Zeng, Shuo-Qi Li, Liang Song*, Jian-Min Zeng, Frontiers of Materials Science (IF1.471). 2018, 12(2): 198–206.

[9] RC Zeng, ZG Liu, FZ, SQ Li, QK He, HZ Cui, EH Han. Corrosion resistance of in-situ Mg–Al hydrotalcite conversion film on AZ31 magnesium alloy by one-step formation, Trans. Nonferrous Met. Soc., 25(6), 2015: 1917-1925.

[10] Corrosion resistance of in-situ Mg–Al hydrotalcite conversion film on AZ31 magnesium alloy by one-step formation, Rongchang Zeng*, Zhen-guo LIU, Fen ZHANG, Shuo-qi LI, Qing-kun HE, Hong-zhi CUI, En-hou HAN.Trans. Nonferrous Met. Soc.,25(6), 2015: 1917-192.

[11] Corrosion of the in-situ grown MgAl-LDH coating on aluminum alloy. Fen Zhang, Chang-lei Zhang, Liang Song, Rong-chang Zeng, Zhen-guo Liu, Hong-zhi Cui. Trans. Nonferrous Met. Soc.,25(2015) 3498−3504.

[12] Corrosion Resistance of Superhydrophobic Mg-Al Layered Double Hydroxide Coatings on Aluminum Alloys. Fen Zhang*, Chang-Lei Zhang, Liang Song, Rong-Chang Zeng*, Lan-Yue Cui, Hong-Zhi Cui1. Acta Metallurgica Sinica (Engl.lett.), 2015, 28(11), 1373–1381

https://blog.sciencenet.cn/blog-114283-1120344.html

上一篇:中车青岛四方机车车辆林化强博士来课题组交流

下一篇:镁合金腐蚀研究进展(26)—镁合金表面层层组装DNA涂层耐蚀性能

全部作者的精选博文

全部作者的其他最新博文

- • 五律 青岛至广州航班

- • 回忆录(2)-我的科学梦

- • 五律 谷雨

- • 回忆录(1)-我的教授梦

- • 五律 紫荆

- • 1995-2023年优秀论文目录